In hand-arm vibration syndrome (HAVS), formerly called 'vibration white finger', the hands and arms are exposed to vibration when using hand-held tools (e.g. pneumatic drills, grinders, chipping hammers). Vibrations or sounds are not responsible for it.

The two main components of HAVS are damage to blood vessels and nerve damage in the arm and hand. Symptoms include whitened fingers (Raynaud's phenomenon) for periods of time while the hands are exposed to cold and pins and needles in the fingers.

In some cases, damage to blood vessels can be reversed after removal from exposure, but nerve damage is permanent.

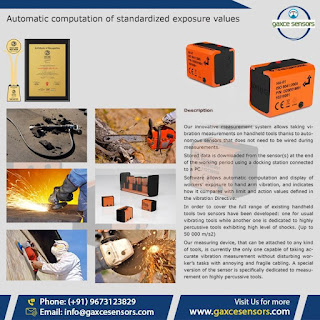

Our innovative measurement system allows for vibration measurements to be taken on handheld tools thanks to autonomous sensors that do not need to be wired during measurements.

Stored data is downloaded from the sensor(s) at the end of the working period using a docking station connected to a PC.

The software allows for the automatic computation and display of workers’ exposure to hand-arm vibration and indicates how such exposure compares with the limit and action values defined in the vibration Directive.

In order to cover the full range of existing handheld tools, two sensors have been developed: one for usual vibrating tools while another is dedicated to highly percussive tools that generate high levels of shock (Up to 50 000 m/s²).

Our measuring device that can be attached to any type of tool, is currently the only device capable of taking accurate vibration measurements without disturbing workers’ tasks with annoying and fragile cabling. A special version of the sensor is specifically designed for measurements on highly percussive tools.

For more details https://gaxcesensors.com/hand-arm-vibration-meterssafety-at-work-made-easy/

https://gaxcesensors.com